Laser welding has really changed the game in manufacturing, bringing levels of precision and efficiency that were pretty much unheard of just a few decades ago. But what often gets overlooked is one of the key behind-the-scenes players: the beam delivery system.

If you’re looking to level up your welding know-how, getting a handle on how beam delivery works is non-negotiable. In this guide, I’ll walk you through the nuts and bolts—from laser types and fiber optics to mirrors and troubleshooting. Whether you’re knee-deep in Denaliweld industrial laser welder projects or just starting to explore the craft, there’s something here for you to take away and use.

Understanding Beam Delivery Systems in Laser Welders

Let’s start with the basics. Beam delivery systems are central to the operation of any industrial laser welder. They’re the unseen routes through which laser energy travels, guiding light from the source to your workpiece. And believe me, that journey matters—a lot.

Components of Beam Delivery Systems

- Lasers: Not all lasers are created equal. CO₂, fiber, and solid-state lasers each come with their own quirks and perks, depending on the job.

- Fiber Optics: These slim cables are champs at moving laser light with minimal energy loss. Bonus? They let you position the laser head just about anywhere you need.

- Mirrors: Think of them as traffic directors. If they’re not aligned just right, you can kiss beam focus and intensity goodbye.

Optimization Techniques

Getting the most out of your beam delivery setup means fine-tuning. Misaligned mirrors? That’ll sap your power fast and leave your welds looking like a mess. A little mirror TLC goes a long way.

Same goes for fiber optics—bends or kinks in the line can slowly strangle your beam quality. Keep ‘em straight and regularly inspected.

Troubleshooting Common Issues

Notice your welds looking off lately? It could be an alignment issue or a dirty lens messing with your beam. A grimy lens scatters the laser, which is the last thing you want.

Welding speed also plays a part. Move too slowly and you’ll overheat the material. Go too fast and you won’t get good penetration. It’s a balancing act, but once you spot the signs, they’re easier to fix.

Introduction

Laser welding has made a serious mark on the manufacturing world, and beam delivery systems are one of the biggest reasons why. These systems basically guide the laser from your industrial laser welder right to the material you’re working on—and that journey shapes the quality of every weld.

Here’s a quick breakdown of the core players:

- Lasers: You’ll usually see CO₂, fiber, and solid-state lasers in the wild, each with its strengths.

- Fiber Optics: These guys make laser transport smooth and help maintain pinpoint precision.

- Mirrors: When aligned correctly, they keep your beam focused and fierce.

Problems like messy, inconsistent welds usually come down to poor alignment or dirty components. Regular upkeep and a little attention to detail can really tighten things up. Whether you’re new or a seasoned welder, getting familiar with these moving parts is worth your time.

Got any beam delivery headaches of your own?

Fundamentals of Beam Delivery Systems

At their core, beam delivery systems are about guiding energy from point A to point B—from the laser source to the workpiece. And that path has a direct effect on your weld quality and precision.

Purpose and Function

These systems are designed to move laser energy efficiently and with control. They use a combo of fiber optics, lenses, and mirrors to shape the beam and direct it exactly where it needs to go. For example, fiber optics keep the beam intact over long distances, while mirrors steer it precisely.

It’s not just about transport—it’s about targeted delivery. You want that energy hitting the exact spot, with minimal loss.

Importance in Laser Welding

In the context of an industrial laser welder, beam delivery is a make-or-break deal. Misaligned mirrors or low-quality fiber optics can throw everything off. Weak welds? Uneven seams? It might not be your welding technique—it might be the delivery system.

Just keeping the parts clean and lined up can boost consistency more than you’d think.

| Component | Function |

| Fiber Optics | Transporting laser light |

| Mirrors | Redirecting the beam |

| Lenses | Focusing energy on the workpiece |

Honestly, a little regular maintenance can go a long way here. I like to check things periodically rather than wait for issues to pile up.

Types of Beam Delivery Systems

Not all beam delivery setups are built the same. Depending on what you’re working on, the system design can vary quite a bit. That variety makes a huge difference in how efficient your industrial laser welder is—and how clean your welds turn out.

Free-Space Beam Delivery

This type relies on mirrors and lenses to channel the laser directly to the target. The cool thing is, it gives you a lot of room to adjust the beam’s shape and focus. I’ve worked with setups that span up to 10 meters—flexible, but they need precise alignment, or you’ll lose a chunk of your energy along the way.

Great for big pieces, though, where fiber might not be ideal.

Fiber-Optic Beam Delivery

Now, fiber-optic systems are the go-to when you need flexibility and compact routing. They snake around corners, ignore dust, and hold up well in tricky environments. Some systems can stretch over 100 meters without a hitch—pretty impressive.

They shine in situations where space is tight and precision is key.

Hybrid Systems

Why choose one when you can combine both? Hybrid systems use fiber for long-distance travel and free space for last-mile targeting. Robotic welding setups often lean on this combo—it offers precision and adaptability, especially when you’re working with odd materials or varying conditions.

Components of Beam Delivery Systems

The guts of your beam delivery system—especially in an industrial laser welder—are what keep everything running smoothly. Let’s dig into the main parts and why they matter.

Mirrors and Lenses

Mirrors redirect; lenses focus. It sounds simple, but choosing the right types and keeping them aligned is absolutely essential. Dielectric or metallic mirrors, convex or concave lenses—each has a role to play depending on your setup.

Even small misalignments can mess with your beam’s intensity. I like to double-check positioning during regular tune-ups.

Fiber Optic Cables

These are the arteries of the system, carrying laser energy across your workspace. They’re flexible, resilient, and better than ever at resisting interference from the environment.

One thing to watch? The grade of the fiber. Better quality means fewer losses and smoother energy transfer.

Beam Shaping Optics

Sometimes, the beam needs a little tailoring. Beam expanders and collimators tweak the beam’s size and energy spread, which can change how deeply it penetrates the material. If you’re getting inconsistent weld depths, it might be time to revisit these components.

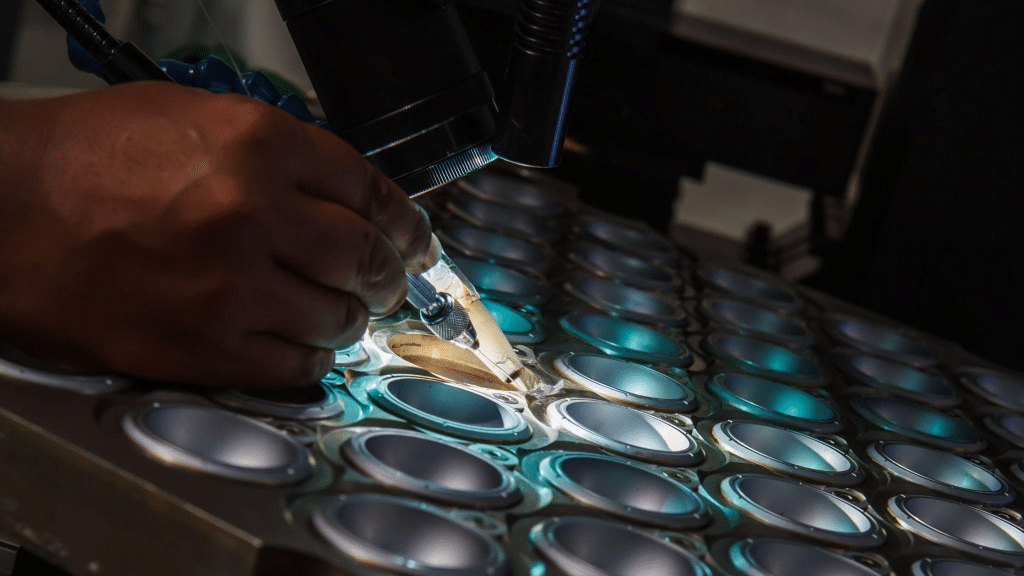

Welding Head

This is where everything comes together. The welding head holds the optics and lens that focus the beam on your workpiece. Different heads cater to different applications—some prioritize speed, others precision.

Keep this part clean and aligned, and it’ll pay you back in clean, consistent welds.

Best Practices for Beam Delivery and Focus

When it comes to using an industrial laser welder effectively, beam delivery and focus can make or break your results. Here’s what I’ve found works best.

Fiber Handling and Routing

Good fiber management is low-effort, high-reward. Protect the cables with proper conduits, avoid sharp bends, and inspect them regularly. A crushed or pinched fiber can quietly wreck your beam quality over time.

Quick checklist:

- Look for bends or damage.

- Use routing guides.

- Fasten cables securely.

- Keep tension even.

Focus Optimization

Dialing in your focus is a bit of an art. Small tweaks to the focal point can change penetration depth and reduce spatter. You’ll want to clean your lenses regularly and adjust focal lengths based on what you’re welding.

It’s subtle work, but the difference is night and day.

Maintenance and Alignment

Nothing flashy here—just good habits. Check your mirrors, clean your lenses, and confirm that your connections are tight. I’ve watched people chase problems in their welds for days, only to find it was a loose mirror all along.

Technological Advancements

Here’s the fun part—tech keeps moving forward, and industrial laser welders are picking up some seriously smart features.

Real-Time Monitoring

Modern systems can track temperature, power levels, and beam stability in real time. It’s like having a second set of eyes on your process. The moment something drifts off course, you’ll know—and can fix it before it ruins your work.

Benefits include:

- Quick fault detection

- On-the-fly adjustments

- Better consistency

Adaptive Controls

These are like cruise control for your welder. The system adjusts speed, power, and focus based on what’s happening in real time. Super helpful when working with materials that vary in thickness or have heat-sensitive properties.

Some applications:

- Compensating for material changes

- Correcting weld distortion

- Optimizing energy output

It’s pretty exciting to see where this is going. I’m curious—do you think this tech will replace traditional techniques, or just enhance them?

Applications Across Industries

Beam delivery systems are the unsung heroes behind laser welding’s success across a wide range of fields.

Automotive

Industrial laser welders are everywhere in the auto world. They’re used to weld frames, panels, and even parts of electric vehicles. The precision and strength are exactly what the industry needs.

Examples:

- Sheet metal joints

- Exhaust system welds

- EV battery connections

Aerospace

Aerospace components deal with intense stress and demand top-tier welding. Laser welding delivers, especially with materials like aluminum or titanium.

Applications include:

- Fuselage welding

- Engine part fabrication

- Lightweight structural joins

Electronics

Laser welders really shine here. With tiny, sensitive components, clean and precise welds are everything. You’ll see them joining battery terminals, circuit boards, and even micro-sensors.

Medical Devices

This field needs ultra-reliable welds with minimal heat damage. Laser welders are ideal for making strong, clean joins in delicate equipment like surgical tools or implants.

Use cases:

- Catheter tubing joins

- Surgical tool assembly

- Diagnostic device connections

Getting familiar with each industry’s specific needs helps you fine-tune your beam delivery system for best results.

Conclusion

Beam delivery systems are the backbone of any industrial laser welder setup. Whether you’re working with a CO₂, fiber, or solid-state laser, your system’s efficiency hinges on how well the beam is delivered. Free-space systems offer flexibility, fiber optics bring reliability, and hybrids balance both.

If you’re struggling with weak welds or erratic performance, chances are your beam alignment, fiber quality, or focus settings need a second look. Staying ahead of maintenance and embracing tech upgrades can give you a real edge in welding quality and productivity. Beam delivery may not be the flashiest part of laser welding, but once you master it, everything else starts to click into place.

Tyler Harrison is a huge horror movie fan always on the hunt for the next big scare. His reviews offer deep insights into classic slashers and the latest releases, exploring themes and innovative techniques. Tyler’s passion for horror makes his perspective essential for any enthusiast.